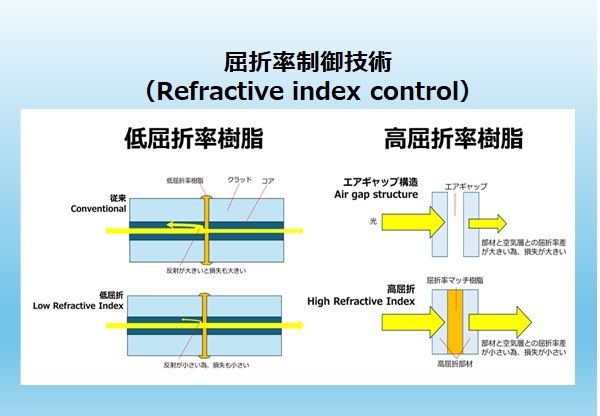

Optical functionalization technology

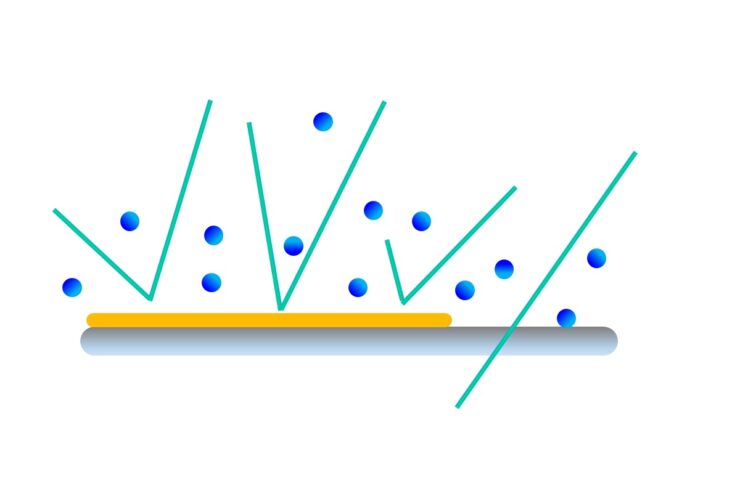

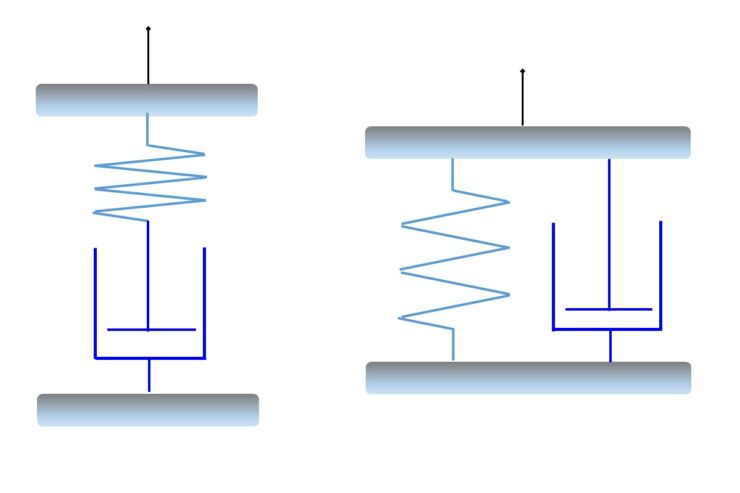

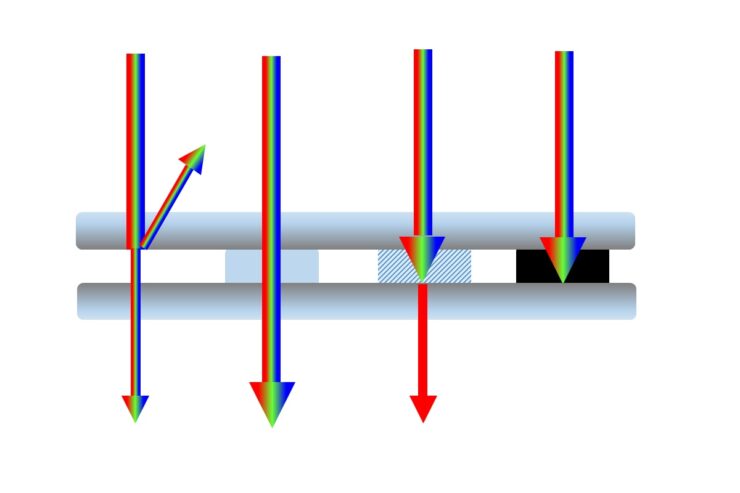

This technology controls the refraction and absorption of light by selecting optimum molecular structures. Diverse optical functions can be added, including a refractive index, Abbe’s number, birefringence, wavelength cutting, light shielding (OD), matte, reflection, and scattering.