Kyoritsu Chemical

News

Three Strengths of Kyoritsu Chemical & Co.

-

01

Adhesion

TechnologiesUV curing adhesives we have developed through our own research offer excellent properties such as high-precision fixing, instant curing, and high airtightness, and are widely adopted in the field of electronics.

-

02

Challenging

Possibilities-

Advanced Evaluation

TechnologiesEvaluation technologies play an important role in the development of new chemical technologies and products. We have introduced some of the world's most advanced analytical systems and are equipped with the highest level of evaluation technologies.

-

03

Solutions

for Your NeedsAs professionals in the fields of polymer chemistry and interfacial chemistry, we create optimal adhesive solutions just for you by sharing in your challenges and dreams and by being creative with ideas geared toward your business.

Product information

We offer a wide range of Kyoritsu Chemical products for various applications, including many highly functional adhesives.

You can search all our products by application, product characteristics, keyword, etc.

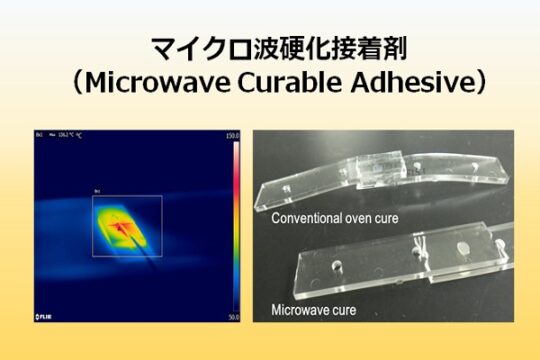

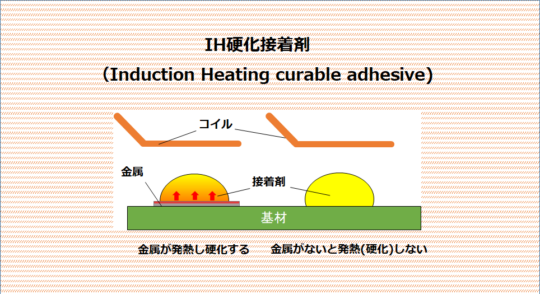

Pickups

We introduce selected products and technologies.

Technical information

We introduce technologies created through

Kyoritsu Chemical's research & development

and related technical information.